Views: 0 Author: Site Editor Publish Time: 2025-12-26 Origin: Site

Composite wall cladding means a fresh building material. It mixes toughness and good looks. These panels usually come from a blend of reused plastic polymers and real wood fibers. At high heat, a set amount of high density polyethylene (HDPE) bonds with wood fibers.

Then, workers extrude and shape it with special machines. This smart mix gives better strength. So, it works great for tough outdoor jobs. In top quality types, makers use co-extrusion methods. They add an outer shield layer from strong polymers like Surlyn over the WPC core.

Second generation wood plastic composite products get made in a twin screw extruder at high heat. At the same time, it forms a guard outer layer, or co-extruded layer, on the wood plastic composite surface. This boosts protection from scratches, color loss, and water entry.

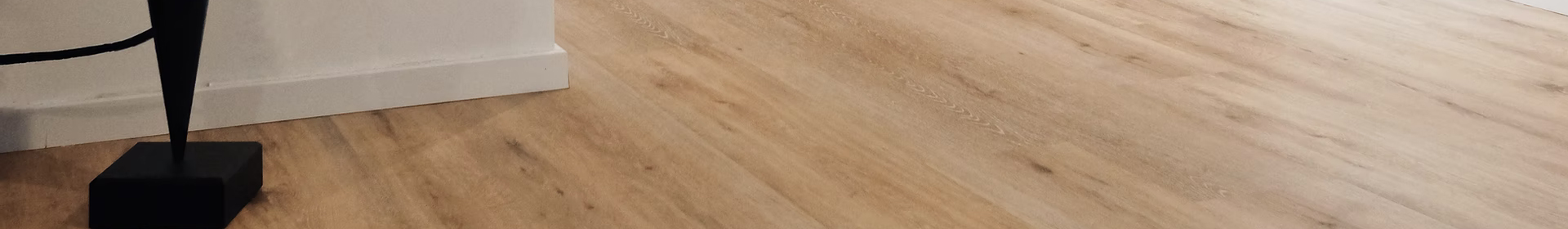

Besides how it works, composite wall cladding comes in many styles. You see brushed feels or 3D wood patterns. This gives choices for modern or old style places.

WPC wall panel systems guard the building's outer layer. They stay dry, fight mold, stop termites, handle UV rays, avoid cracks, resist bending, need no upkeep, and have no formaldehyde. The stuff comes from reused raw items. Plus, it is fully recyclable. These traits help outdoor wall boards block water harm.

They also stop mold spread and fight sun damage. Unlike old wood or vinyl siding, they do well in spots with big temperature changes. These panels cut down on swelling, breaks, and twists. As a result, they keep walls strong and looks nice with little care.

Now, composite panels copy the deep colors and lines of true wood. But they skip the upkeep hassle. Natural grain shades mix with tree heart patterns for a real feel. Many finishes exist, such as IPE, walnut, teak, antique, ashwood, and dark grey. You can pick to fit your building plans.

Design folks like MexyTech’s bicolor slat wall panels for their lively two tone look. This color pair boosts shadows. It also lifts the 3D feel on outside walls. Such picks let WPC wall panel systems fit super new fronts or classic wood house styles.

A big plus of composite cladding is how it handles wild weather. It works from -30°C to 70°C, good for places worldwide. In wet tropics or cold winters, these materials keep their shape. They avoid color fade or breaks. Surlyn coated co-extruded panels give strong UV protection, up to gray scale 4.5. This means they last long even in bright sun.

A key reason builders pick composite over real wood is simple care. It skips paint, seal, or stain jobs like wood needs. Just wash now and then with soft soap. No sanding or new coats either. This cuts costs over years.

Besides body protection, composite cladding aids heat control. Its build lowers heat pass through walls, mainly with right frames and air spaces. This easy insulation helps cooling or heating systems work better in hot or cold times.

Green traits run deep in composite panels. The raw stuff is reused materials, and the item itself can recycle 100%. Many makers, like MexyTech, use old plastics and farm waste such as wood flour or rice husk. At the end, panels recycle easy with little trash.

Feature | Composite Cladding | Natural Wood Siding | Vinyl Cladding | Metal Panels |

Rot/Decay Resistance | Excellent | Poor | Good | Excellent |

Termite Resistance | Yes | No | Yes | Yes |

Maintenance | Low | High | Low | Moderate |

Aesthetic Appeal | Wood like texture + modern finish | Natural wood beauty | Plastic look | Industrial appearance |

Acoustic Performance | Good | Good | Poor | Poor (noisy in rain/wind) |

Lifespan | 15–25 years | 8–15 years | 10–20 years | 20–40 years |

Composite skips problems like termite harm, rot, and splinters. It lasts longer than wood too. Next to vinyl, it takes hits better and looks fancier. Unlike metal panels that rattle in rain, WPC wall panels stay quiet. They also give warmer looks.

Prices for composite wall cladding change a lot by material type. High end WPC panels with stamped finishes cost more than plain ones. Two color styles or custom color matches raise the price per square meter too.

Good setup matters for long life. Pros handle sealing and straight lines to last. Costs for work depend on job size and base setup. Choices like MexyTech’s patented pre-drilled slat wall systems cut setup time by up to 50%.

Upfront price might top vinyl or raw wood a bit. But over time, composite wins on value. Less care means better money return. Homes with nice, tough outside cladding sell for more. That's from better street looks.

Setting up WPC wall panels needs clear steps in layers:

· Get the base frame ready (aluminum joists suit big jobs best)

· Place the first panel straight and even

· Attach with screws in planned slots or open spots

· Leave air gaps to stop water build up

· Add edge seals with trim if needed

Mexytech wall panels have pre-drilled screw spots. They fit all frame types. Setup just means screwing into those holes.

Regular clean up stays easy:

· Mix mild soap in water

· Put it on with a soft brush or sponge

· Rinse light with a hose

· Skip pressure washers; they hurt surface coats

Avoid high pressure washing that may damage surface coatings

Composite wall cladding lasts well by design. But checks now and then stretch its life:

· Check once a year for loose screws or seal breaks

· Swap out scratched or broken boards

· Clear plants from around it

Fixing bad panels is easy thanks to their piece by piece build.

When buying from far off makers, check them close. Seek known names with real skills, like MexyTech. MexyTech Co-extrusion WPC (suprotect) slat wall cladding sells well overseas. That's because its look and build come from our own design and work. It has special tools, fast making lines, and world shipping.

Check for matches to CE, ISO9001, FSC marks. Seek proof tests in spots like:

· Fire hold (EN 13501-1 B-s3,d0)

· UV steady (QUV tests 3000h)

· Strength pull (ASTM D1761)

Good sellers give papers to back their claims

MexyTech shines by giving:

· A full set, from plain WPC wall panel picks to ASA based Novascend line

· Our own design fixes that boost work and cut setup time

· Green making with reused start materials

· Help on tech from start talk to after setup tips

Provides technical support from design consultation to post installation guidance

With proper installation, WPC cladding can last 15–25 years depending on product grade.

Yes, it offers excellent water resistance thanks to its polymer composition and sealed surface layer.

DIY is possible for small projects, but professional installation ensures best performance.

High quality options like MexyTech’s co-extruded boards have UV ratings up to gray scale 4.5.

Yes—most WPC systems are made from recycled materials and are 100% recyclable at end of life.

Exploring Exterior Wall Cladding: Key Benefits of Composite Materials

Beyond Aesthetics: Fire Safe WPC Cladding Design in the Wake of the Hong Kong High Rise Blaze

Why Eco-Friendly Exterior WPC Wall Cladding is Replacing Traditional Tiles

Can Outdoor Wall Cladding Withstand Harsh Weather Conditions?