Views: 55 Author: Site Editor Publish Time: 2022-07-06 Origin: Site

Over the last two years, production across the globe was put on hold as the world endured a worldwide pandemic. As the number of cases are decreasing globally, the world is slowly opening back up and more restrictions are loosened. The construction is also beginning start back up as well. Like many industries affected by COVID-19, many are also facing supply chain difficulties. Globally, there is a growing shortage of wood, causing wood-reliant industries to seed out alternatives. One of these alternatives is Wood Plastic Composite. This material combines both environmentally plastics with wood to create a durable option for the construction industry.

So how does the market of Wood Plastic Composites look in North America? And what is the outlook for the future? This article will deep dive into the insights of the market and analyze the different segmentations. It will also examine the factors that drive and restrain the market and observe the developments of the material. Finally, it will evaluate the impact of COVID-19 as well as assess the projected growth of the Wood Plastic Composites industry.

In 2020, the Wood Plastic Composite market size was $5.4 billion USD. By 2030, the industry is expected to pass $13 billion and have a growth rate of over 13%. The market is primary driven by North American construction businesses that primarily use polyethylene-based Wood Plastic Composites. The market is continuously growing because of its environmentally friendly trait and high demand from the construction industry. However, the high initial costs may be a limitation for the material. Currently, a large amount of investment is going into research and development is going into improving Wood Plastic Composites. This will make it an even more viable option for construction companies, which is expected to further drive demand. COVID-19 has affected the Wood Plastic Composite industry for a short period of time. However, the market is also expected to grow strong in the next few years.

The market for Wood Plastic Composites is mainly split into three main segments: location, industry, and material of plastic composite.

Location

The continents with the highest demand for Wood Plastic Composites are: North America, Europe, and Asia Pacific. Of these continents, North America accounted for 52.6% of the market and had a revenue of 2.12 billion USD. This is due to a growing population and reduction of the North American household size increasing the demand for housing. Over the next few years, North America is projected to remain as the largest market for Wood Plastic Composites. This is largely due to the high number of manufacturers located on the continent. This, in turn increases the construction industries reliance on Wood Plastic Composites. However, the construction industry is not the only reason for the large Wood Plastic Composite market in North America. There has been a growing boom for homeowners to reconstruct and remodel old homes which also contribute to demand.

Industry

The main end-use industries that use Wood Plastic Composites are building and construction, automotive and consumer goods. Because of its ability to improve strength, Wood Plastic Composites are primarily used for decking within the construction industry. This includes anything from siding, fencing, garden landscaping, extension of living areas, alternative to stone-based features, and residential decks. This usage accounts for more than 90% of the Wood Plastic Composites within the building and construction industry. The main reasons driving demand for Wood Plastic Composite as a material within the industry is the rapidly increasing housing demand and emphasis on green materials. However, the construction industry is not the only one reliant on Wood Plastic Composites. The reliance from the automotive industry is rapidly growing as well. This is due to the lightweight nature of Wood Plastic Composite making it an ideal material for cars and automotives.

Material

The main plastic composite materials are separated by polyethylene, polypropylene, and polyvinyl chloride. Of these materials, polyethylene is primarily used in Wood Plastic Composites making up 69.4% of the market. There are many benefits which explain why Wood Plastic Composites comprised of polyethylene make a good option for construction. Its unique molecular structure and special arrangement of molecules strengthens the composite and increases longevity and durability. Furthermore, it allows polyethylene-based Wood Plastic Composites to have a higher performance compared to other resin-based Wood Plastic Composites. This is because this combination possesses the versatility and processability of wood. Like polyethylene, it can easily be molded into different shapes and sizes. Finally, its cost-effective nature makes this combination makes polyethylene-based Wood Plastic Composite very attractive.

There are many benefits to Wood Plastic Composites that drive the market. The primary factors are the material’s eco-friendly characteristic and construction industry’s high demand.

Environmental Factors

With growing environmental concerns, companies are finding more ways to increase their offerings of eco-friendly products. Wood Plastic Composites are comprised of many different materials. This allows researchers to find environmentally sensitive alternatives for the plastic portion. Currently, many of these products are made with plant-based fibers and have minimal use of toxic chemicals. This makes the composites biodegradable, emit low CO2 levels during production, and have high renewable properties. Furthermore, because of the environmentally beneficial nature of Wood Plastic Composites, the need to log trees for new decks decreases.

Demand in Construction Industry

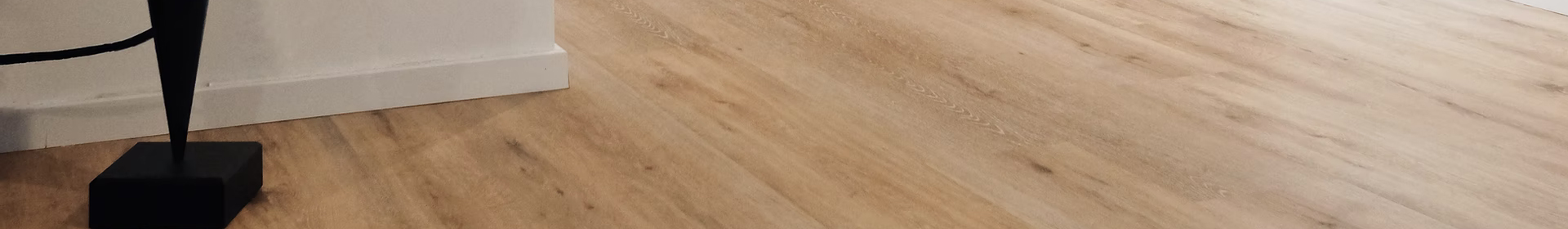

Currently, Wood Plastic Composites are highly sought after in the construction industry. This is because the material has similar aesthetics to wood while maintaining the properties of plastic. The wood-like quality of Wood Plastic Composite gives any construction projects a classy appearance. While the flexible and durable nature of plastics allow the Wood Plastic Composites to be easily molded into any shape. These two characteristics combined give the material a beautiful look while remaining sturdy. Furthermore, Wood Plastic Composites are easy to maintain, does not crack or warp, and is water resistant. All these factors contribute to the high demand of these composites.

The main restrain for the market of Wood Plastic Composites is the high initial cost. Compared to raw wood material and plastic, Wood Plastic Composites have a higher cost associated with it. These costs are associated with research and development, purchase, and installation. Furthermore, because this material is also comprised of plastics and resin, expansion and shrinkage from temperature is also an issue. As a result, countries with a high supply of raw wood material may opt to use wood over composite materials.

Wood Plastic Composites are one of the most used material in the construction industry. Because of this, companies are continuously researching on how to improve the attributes and characteristics. There are many new technological developments that continuously improve the material and lower the environmental burden of production:

· Teknor Apex Company – Created a highly weatherable compound for the outer layers of dark Wood Plastic Composite Decking. This allows for greater durability of the item and allows for it to be scratch resistant. Not only is this new product sturdier, but it also has lower maintenance requirements and can last longer.

· KTH Royal Institute of Technology – Developed a transparent Wood Plastic Composite that is 100% renewable by recycling waste from the orange juice industry. Because this composite is transparent, it serves as an alternate for windows.

· AZEk Building Company – Built a new plant solely for expanding production of Wood Plastic Composite focusing on using recycled Polythene.

In 2020 and 2021, many industries across the world had been negatively impacted by COVID-19. This includes the construction industry. Lockdowns implemented by governments in attempt curb the spread of the virus had sent many construction workers home. This caused operations of the construction industry to come to a halt. Furthermore, the lockdowns caused the supply chain for all products to be severely limited during those two years.

However, recent COVID-19 developments show a positive trend for the construction industry. The demand in the residential housing sector has seen a rapid growth as more pandemic restrictions are loosened. This growing demand is also increasing the number of new development projects. These new projects are expected to drive the market for Wood Plastic Composites. Furthermore, there has been a recent trend of reconstructing and remodeling old homes in the United States. This trend is expected to further increase the demand for construction as well as Wood Plastic Composites.

Despite the temporary pause in growth resulting from COVID-19, the projected market for Wood Plastic Composites is looking favorable. Its environmentally friendly nature and the growing dependence by the construction industry allows the material to continuously be sought after. The demand for Wood Plastic Composites is expected to grow healthily in the next ten years. Technological advancements to the product that make it even more viable as a construction material staple will also drive demand. In 2020, the global Wood Plastic Composite market was valued at $5.4 billion USD. The market is expected to surpass $12.99 billion and have a compound annual growth rate of 12.10% by 2028. The projected growth of the Wood Plastic Composite market shows the reliability of the product for the construction industry.

As an experienced WPC products manufacturer in China, we offer factory prices and good quality products for projects and homes. Our team is always ready to offer advice or answer your questions. Contact us to get advices today!

Foshan MexyTech Co., Ltd.

Website: https://www.mexytech.com

Cellphone/WhatsApp/Skype/Wechat: +86-13824532263

Email: info@mexytech.com

2025 Building Trends: Why Architects Are Switching to Carbon-Neutral Exterior Wall Cladding

What Are the Latest Developments in Wood Plastic Composite (WPC)?

Designer-Approved Texture, Contractors' Budgets Delight: 3D WPC at 15% Lower TCO

What Factors Influence the Price of Composite Decking per Square Foot?

Slat Composite Fence: Modern Durable Outdoor Fencing Solutions

Does WPC Fencing Provide Sound Insulation? Real Test Data Explained

A Specifier's Dream: The WPC Fence That Withstands 9-Level Winds